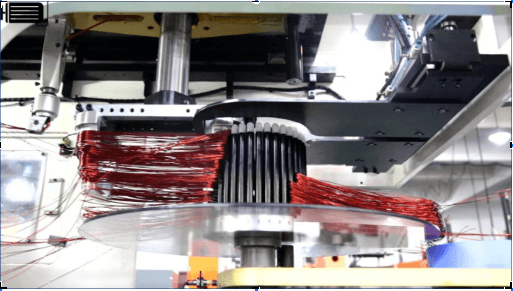

Preface to Motor Stator

Motor stator winding machines are critical in the product of motors, as they insure the precise winding of the bobby line onto the stator core. This process is essential for creating high- performance motors that meet assiduity norms. Stator winding machines automate the intricate and repetitious process of winding coils on the stator core, reducing mortal error and perfecting the overall effectiveness of the manufacturing process. With the ever- growing demand for electric motors across colorful diligence, similar to automotive, renewable energy, and artificial ministry, the affordability of the stator winding machine price has become a major consideration for manufacturers. A high- quality, affordable machine can significantly reduce overall product costs, giving businesses a competitive edge while maintaining excellence in product quality.

Affordable Stator Winding Machines

The price of a stator winding machine plays a pivotal part in making advanced manufacturing accessible to a broader range of diligence, including small and medium- sized enterprises( SMEs). With electric motors getting decreasingly common in colorful sectors, companies are looking for ways to reduce costs without compromising on quality. Affordable motor stator winding machines allow manufacturers to streamline product, reduce homemade labor, and maintain perfection without overreaching their capital investment.

- Makes advanced manufacturing accessible to small and medium- sized enterprises The lower outspoken costs of these machines make it doable for lower businesses to borrow robotization and keep pace with larger manufacturers.

- Balances affordability with high performance, enabling cost-effective scaling With the capability to gauge product efficiently, manufacturers can meet increased demand while maintaining cost- effectiveness.

- Provides dependable results that meet product requirements without high capital investment Businesses can invest in high- performance winding machines at a lower cost, boosting their productivity and competitiveness.

- Offers inflexibility for manufacturers to handle adding demand for electric motors These machines are customizable, allowing for the adaption to colorful winding patterns and motor specifications.

- As diligence evolve and expand, the availability and affordability of motor stator winding machines are crucial to icing manufacturers can gauge operations while delivering high- quality products.

Motor Stator Winding Machines

Motor stator winding machines are designed to automate the winding process, icing harmonious quality, perfecting outturn, and reducing homemade labor. By automating this critical step, manufacturers can achieve advanced product volumes, lesser perfection, and more harmonious results. These machines offer several significant advantages

- Advanced Product thickness With automatic winding capabilities, each stator is wound precisely according to preset specifications, icing invariant quality across product batches.

- Reduced Homemade Labor robotization reduces the need for mortal intervention, lowering labor costs and the eventuality for crimes.

- Increased product Speed These machines operate at advanced pets compared to homemade winding processes, significantly adding the overall outturn of the product line.

- Lower functional Costs As the machine performs repetitious tasks more efficiently, manufacturers can produce further units in lower time, reducing the cost per unit.

Honest automation’s

Honest automation is a leader in furnishing motor stator winding machines that offer both perfection and cost- effectiveness. With a focus on delivering affordable, high- quality robotization results, honest automation helps manufacturers ameliorate their product lines by offering a range of machines designed for colorful operations. Their motor stator winding machines incorporate state- of- the- art technology, offering manufacturers the capability to customize the winding process, cover real- time data, and optimize product workflows.

- Crucial features of honest automation’s stator winding machines include

- Real- time Monitoring Systems These systems track machine performance and product data, icing that each stator is wound to specification.

- Malleable Winding Settings Manufacturers can program and acclimate winding patterns and line pressures to suit specific motor conditions.

- Stoner-Friendly Interfaces Easy- to- use controls help drivers snappily acclimatize the machine to different motor designs, icing smooth transitions between product batches.

- Continuity and trustability honest automation’s machines are designed to last, minimizing conservation costs and time-out.

Future of Affordable Motor

As the global demand for electric motors continues to increase, the need for affordable, high- performance stator winding machines will grow in tandem. diligence like electric vehicles( EVs), renewable energy, and artificial ministry will continue to drive demand for more advanced motor technologies. In this evolving geography, affordable motor stator winding machines will come indeed more pivotal to insure manufacturers can meet demand efficiently without immolating quality or perfection.

With companies like honest automation leading the way, the future of motor stator winding machines looks promising. inventions in machine design, robotization, and accoutrements will continue to make these machines more effective and cost-effective. Features similar as prophetic conservation, AI- grounded optimization, and IoT integration will make the machines indeed more adaptable and able to handle adding product volumes.

Conclusion

Motor stator winding machine are integral to effective motor products, and their affordability is crucial to maintaining competitive product lines. The stator winding machine price, when balanced with the machine’s quality and functionality, makes it a vital asset for manufacturers. With dependable and cost-effective results from companies like honest automation, manufacturers can ameliorate their product capacity, enhance product thickness, and meet request demands without stretching their budgets.